ENGINEERING & SERVICES

ENGINEERING & SERVICES

At G.K Engineering Works, we use the latest technology which helps us to deliver better accuracy as well as quality.We have a completely customer-centric approach that allows us to customize our product as per the individual specifications of the customer.

Below is a brief description of our manufacturing capabilities and advancements.

TYPES OF ENGINE VALVES MANUFACTURED AT G.K. ENGINEERING WORKS

G.K. Engineering Works is engaged in manufacturing engine valves of all type of internal combustion engines. Depending on the material used and type of post-machining hardness, the following types of engine valves are available with us.

1) Monometallic Engine Valves ![]()

2) Bimetallic Engine Valves ![]()

3) Full Steel Engine Valves ![]()

4) Nitrated Engine Valves ![]()

5) Chrome Coated Engine Valves ![]()

6) Induction Surface Hardened Engine Valves ![]()

7) Tip-Tempered Engine Valves ![]()

8) Customized Engine Valves ![]()

MANUFACTURING AT G.K. ENGINEERING WORKS

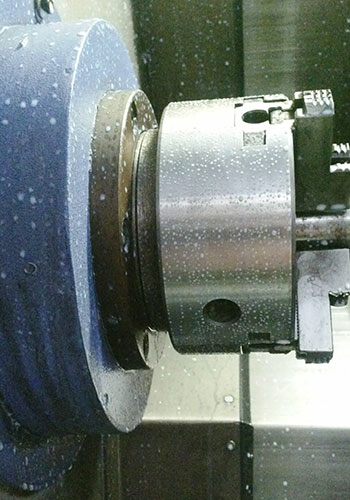

The manufacturing process at G.K. Engineering Works follows strict quality and process controls. For achieving close to zero defects, we use the latest Computer Numerical Control (CNC) technology. Along with it, we have a wide collection of Center-less Grinders, Semi- Automatic Copying machines, Imported Seat Grinders, Traditional Lathe machines and other ancillary gadgets to assist in production.

PACKAGING

Each valve is chemically washed and thoroughly cleaned afterwards. It is then coated with a layer of oil to ensure it remains rust-proof, thus ensuring our impeccable high standards of quality. Each set is then carefully packed hereafter in our EUROSTAR®& KINGSTON® boxes & readied for dispatch.