Quality

Quality

At G.K. ENGINEERING WORKS, quality is always given the utmost importance. We have divided our quality into three sections:

1) General and overall quality:

G.K. Engineering Works is an ISO certified enterprise (German Certification, Dakks). We take all measures to ensure that our overall high standards of safety and quality are maintained.

AN ISO 9001:2008 ENTERPRISE

2) Inspection & Testing:

(a) Raw Material Evaluation: Our raw material is carefully examined and then selected. Since it is the first step of the manufacturing process, a lot of emphasis is laid on proper selection of the desired raw material.

(b)Process Control: Proper steps are taken during every process to ensure the good quality of the product.

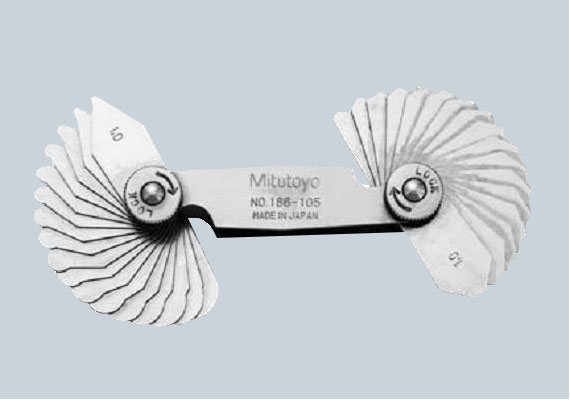

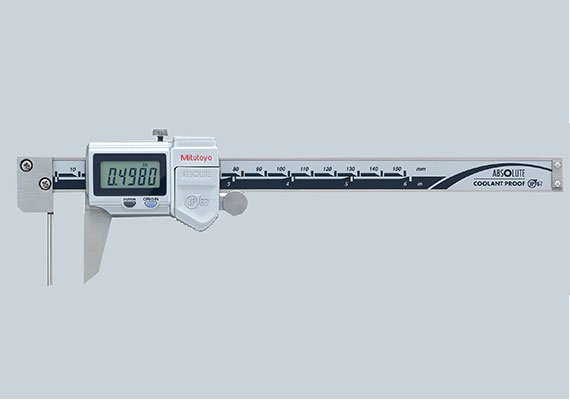

(c) Measuring Instruments: All parameters of every piece that is manufactured at G.K. Engineering Works are measured carefully to ensure close to zero defects in our product. We have a number of measuring instruments like Dials & Dial Stands, Radius Gauges, Micrometers, Vernier Calipers, and other gauges.

(d) Packing Control: After mechanical measurement, every piece is checked thoroughly with the naked eye while packing. It is carefully coated with a layer of oil to prevent rusting. A lot of emphasis is laid on ensuring that the quality of packaging in our EUROSTAR boxes is as per set standards of G.K. Engineering Works.

3) Hardening to ensure the long life of the product:

There are various processes of hardening untaken to ensure that the engine valve remains efficient even at high temperatures. It also reduces the wear and tear of the valves by a big margin.